We have developed specialist processes and systems for gas, oil and petrochemical engineering

We have unrivalled expertise in designing and developing innovative solutions for the oil, gas and petrochemical sectors.

With a proven track record for delivering high-profile national and international projects on time and within budget, our tailored approach will ensure you gain maximum value from the life-cycle of your facilities.

Whether you require comprehensive project management or support with a single element of your project – from design to engineering to facilities management – we can adapt our services to match your precise needs.

Primary areas of expertise

Planning

Design

For the production of drawings we are adept at utilising both MicroStation and AutoCAD for creating detailed 3D visualisations, including:

- Engineering Line Diagrams (ELDs)

- Piping and instrumentation diagrams (P&IDs)

- Flow diagrams

- Mechanical/civil general arrangement drawings

- Detailed sections

- 3D models

- Isometrics

- Strip maps

- Loop and wiring diagrams

We can also produce precise 3D visualisations of our skid units, site rebuild projects and other aspects using Plant 3D.

Design Appraisal

We have staff qualified to appraise designs against the IGE/GL5 standard, including for gas, mechanical aspects, process and corrosion control.

Our expertise extends to:

- Low and high-pressure pipelines in steel and PE

- Pressure reduction stations and other AGI’s

- Block Valves

- Pig-trap installations

Stress analysis

As the owners and occupiers of Caesar II stress analysis software, we have a wealth of expertise and capability in conducting stress analysis on gas and petrochemical pipework.

Land Surveying

We can arrange fully approved land surveys applicable for planning applications, strip maps and AGI design processes.

These surveys involve both advanced GPS equipment for outlining the route and versatile AGI site surveys.

Electrical

We produce fully compliant designs for power and lighting circuits, including three-phase supplies to large rotating machinery.

Instrumentation and control

We design advanced control systems fully compliant with engineering standards through our experienced team of Instrumentation and Control Engineers.

Environmental

We can conduct Environmental Impact Assessments on your behalf, including field surveys and project-specific Environmental Management plans.

We also provide consultancy services should you prefer to carry out the assessment yourself.

Engineering

Pipeline engineering

We are the experts in pipeline engineering.

We have taken the lead on a host of high-profile pipeline projects; from multi-million-pound pipelines to smaller-scale pressure reduction facilities, underground to above ground installations.

Our finely-tuned processes ensure pipelines and the facilities they link to comply with all relevant governmental regulations, client and stakeholder requirements.

We develop solutions that enable you to proceed with less risk, save on costs (material, equipment and construction) and streamline project timescales. Our pipeline services include:

- Project management

- Feasibility studies

- Hydraulic flow modelling

- Engineering and design

- Procurement

- Construction management

- Pipeline integrity consulting

Process engineering

We develop detailed process models using our team of dedicated engineers and our own specialist software, designed for gas pipelines and above ground installations.

We also use Stoner SynerGEE pipeline modelling software. Among the most advanced pipeline simulation software options, SynerGEE facilitates the modelling of pipelines including:

- Natural gas

- Propane

- Steam oxygen

- Air

For natural gas pipelines, this software facilitates modelling of closed conduit networks of pipes, regulators, valves, compressors, storage fields and production wells.

Mechanical engineering

We create fully compliant mechanical engineering designs for the UK, EU and international oil, gas and petrochemical industries.

Our designs meet both European and international engineering standards, including:

- BS EN 8010:2004

- BS EN ISO 14723:2002

- IGE TDs

- ASME B31.8

- ASME B31.4

Civil and structural engineering

We have a proven track record for creating effective designs across all primary aspects of civil engineering, including:

- Structural steelwork

- Reinforced/mass concrete

- Brickwork and masonry

- Timber (incorporated into roads, drainage, housings or control rooms)

- Foundations and retaining walls

- Masts

- Cabling ducts

Acoustic engineering

We can accurately assess the acoustic ramifications of new or existing developments to keep noise levels in check.

Management

Project management

We have successfully managed projects involving everything from multi-million-pound pipelines to smaller-scale PRIs or AGIs.

Our holistic approach to project management utilises Gantt charts and other data visualisations, and all management processes can be synchronised with a wide range of project management tools.

Risk and safety management

We can manage all potential risk/safety factors in accordance with Construction, Design and Management (CDM) regulations (2015). Our processes involve:

- Planning supervision

- Project-specific health and safety planning

- Risk assessments (including full quantitative risk assessments)

- Running/reporting HAZIDs, HAZOPs and HAZCONs

- Liaising with the Health & Safety Executive (HSE)

On line inspection

We are adept at inspecting and cleaning long, high-pressure gas pipelines, operating pig-traps and conducting tracking processes.

Land agency

Our experienced Land Agents are experts in both cross country pipelines and AGI’s from development through to the operational maintenance stages.

Cathodic Protection

Cathodic protection

What is Cathodic Protection

Cathodic protection (CP) is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded “sacrificial metal” to act as the anode. The sacrificial metal then corrodes instead of the protected metal, this is known as a Galvanic or Sacrificial Anode CP system (GACP or SACP). For structures such as long pipelines, where galvanic cathodic protection is not adequate, an external DC electrical power source is used to provide sufficient current, this is known as an Impressed Current CP system (ICCP).

Common applications for CP are steel Gas, Oil or water pipelines, steel storage tanks, steel jetty piles, ship and boat hulls, offshore oil platforms, onshore oil well casings, offshore wind farm foundations and metal reinforcement bars in concrete buildings and structures.

We have specialist Cathodic Protection Engineers able to conduct field-based resistivity surveys that will enable you to determine:

- Ground bed size/location

- Size/number of fixed anodes on smaller buried pipe systems

Cathodic Protection surveys provided by Saith:

-

- DC and AC potential logging, DC and AC current density logging, Soil resistivity surveys,

- Close Interval Potential Survey (CIPS)

- Direct Current Voltage Gradient (DCVG) coating survey

- Pipeline Current Mapping survey (PCM)

- Fault finding, system performance audits

- Pipeline locating and depth of cover surveys

- Pre-CIP survey

- Line-walking and ROW surveys

- Scrub clearance of pipeline ROW

Saith conducts pre‐design surveys, specialized surveys, supply of materials, design, installation, energizing, testing and commissioning, monitoring and troubleshooting of a wide range of cathodic protection projects.

Typically, industrial cathodic protection involves structures such as underground and aboveground storage tanks, buried pipelines, oil well casings and structures associated with refineries, power plants, water treatment and desalination plants, etc.

Studies

Saith’s Cathodic Protection engineers can carry out FEED studies and consultancy services on all major projects. Studies can be carried out on pipelines, well casings, tank farms, Jetties and reinforced concrete structures.

Saith provides the following studies:

-

- Feasibility and site selection

- Project Scoping

- Conceptual design studies

- Induced AC modelling

Saith’s in house design team provide unrivalled expertise in all aspects of Cathodic Protection design. Our senior engineers are registered on the G-17, G-35 and PS-6 databases and can provide Approval and Appraisal for any design works.

Saith provides the following design services:

-

- Conceptual and detailed design of: Pipelines, Above Ground Installations (AGI), buried tanks, above ground tank bases, Jetties and Harbours.

- Material and equipment selection and specification

- Design approvals and appraisals. (G17, G35, PS6)

- Audits and reviews

- Drawing record updates (including as-built)

Our drawings are produced in either 2D or 3D models depending on the project and the requirements of our clients.

Saith supply a wide range of products used in cathodic protection. We also use strategic partners for specialist materials, which enable us to offer a complete range of cathodic protection materials and associated products.

Saith provides the following CP materials:

-

- Magnesium, Zinc and Aluminium Sacrificial anodes in pipeline, hull, tank or ribbon applications

- MMO impressed current anodes in tubular, ribbon, wire or canister applications

- Silicon Iron impressed current anodes

- Coke breeze backfill for use with impressed current anodes

- All types of CP cables armoured or unarmoured, including XLPE/PVC and PVDF/HMWPE.

- CP Instrumentation including, Pin braze equipment, Soil resistivity equipment, Data loggers, Timers/interrupters, Insulation and Isolation testers, Multi-meters and Swain clamps.

- CP Test posts, Control pillars and Junction boxes made to any client specification

- Both portable and permanent Reference Electrodes in Copper/Copper Sulphate and Silver/Silver Chloride Seawater

- Both AC and DC coupons in Saddle, Flat or Encapsulated construction

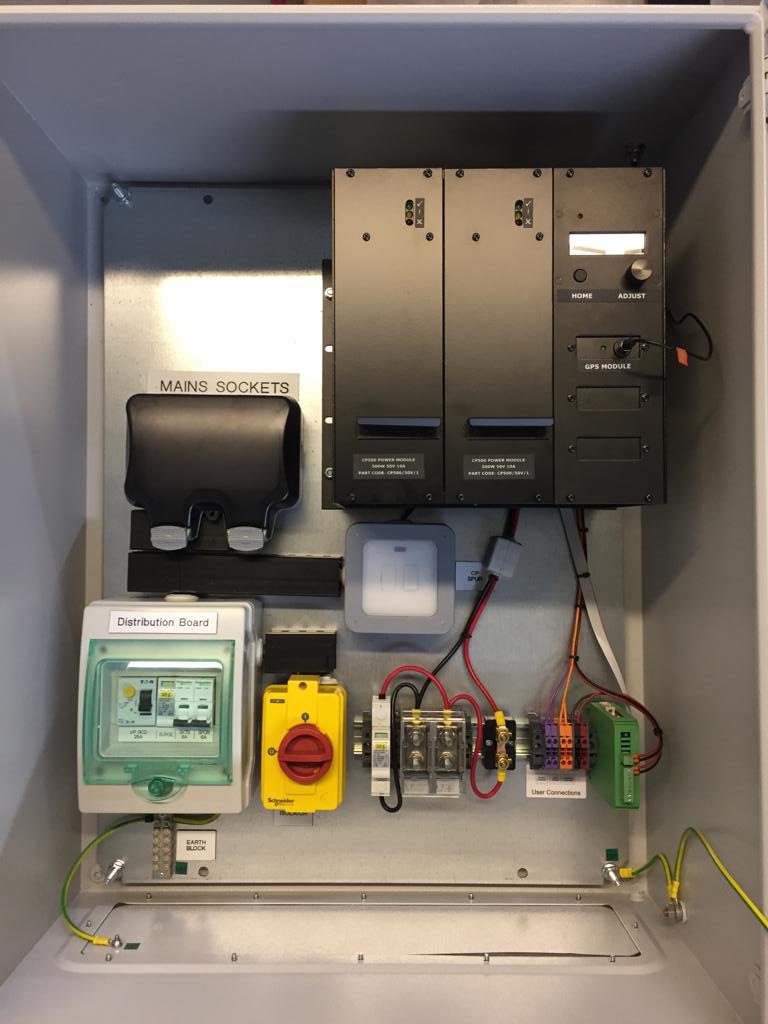

- DC power supplies in any variation up to 50V/50A. Power units can be supplied for any application. Power units can be housed within wall or floor mounted enclosures or within any other custom enclosure. Power supply options include: Integrated interrupter unit, GPS Module for Interrupter synchronisation, USB Port for local communication, TCP/IP Remote communication, GSM Remote communication and SMS Remote communication

- Pipeline insulting flange kits Type D, E & F for pipeline diameter 15mm to 600mm and ANSI 150 to 1500

- Isolating Spark Gaps. Hazardous and non-hazardous zone applications

- Solid-state polarization cell and Solid-state DC de-coupler

- Earthing electrode gradient control wires, zinc and copper

- Flange protectors: Stainless steel and clear PVC type for pipeline diameter 15mm to 3700mm and ANSI 150 to 2,500 and API 2,000 to 15,000

- Pipeline connections: Thermit weld kits, welded pads to any pipeline specification and pin braze connections

- Remote monitoring units for either Transformer Rectifiers or Test Points

Saith’s engineers can provide detailed audits of cathodic protection systems, interference investigations and pipeline integrity assessment surveys. These surveys are used in feasibility studies, conceptual and detailed designs, routine monitoring and investigations and audits to help predict or asses a structures general condition, the effectiveness of its CP system, quality and condition of its coating and provide future operational recommendations.

-

- CP surveys including: DC and AC potential logging, DC and AC current density logging, Soil resistivity surveys,

- Close Interval Potential Survey (CIPS)

- Direct Current Voltage Gradient (DCVG) coating survey

- Pipeline Current Mapping survey (PCM)

- Fault finding, system performance audits

- Pipeline locating and depth of cover surveys

- Pre-CIP survey

- Line-walking and ROW surveys

- Scrub clearance of pipeline ROW

Procedural expertise

Commissioning

We have specialist expertise in project commissioning for proposed or existing installations. We ensure adherence to operational requirements in relation to:

- Design

- Procurement

- Installation

- Testing

- Operability

- Maintenance

We implement procedures that ensure each operational component – whether it be a single instrument or whole module/system – is inspected and tested in line with applicable requirements.

Due diligence

We independently appraise and verify the viability of engineering projects using technical feasibility assessments.

The quality of our due diligence practices is reinforced by our extensive experience of pipeline design, installation and maintenance. Through these processes, we can:

- Assess value

- Reduce risk

- Make recommendations

- Guide future projects

Whether you are appraising a proven design or element of immature technology, our comprehensive approach will ensure you gain maximum value from every project.

Contact Saith Limited to find out how our extensive expertise could help add value to your next project.