Engineering services adapted to match your precise requirements

Develop innovative engineering solutions on time and within budget with our comprehensive range of engineering services.

Working primarily with clients from the oil, gas and petrochemical sectors, our services cover all stages of design and implementation; from initial feasibility studies through to manufacturing/construction.

Whether you require a one-off service or full turnkey solution, our extensive range of services can be optimised to suit your exact needs.

Agility and dynamism define our services. Our company model enables you to commission scalable solutions at a more competitive cost and allows us to work closely with clients to deliver on their requirements.

Comprehensive feasibility studies

Avoid project delays, spiralling costs and missed opportunities with our comprehensive feasibility studies.

These studies will give you the insight you need to decide whether to push your project forward to the next engineering stage.

Using engineering and cost analysis, we can help you identify any potential issues ahead of time. This enables you to avoid project delays and unnecessary expenditure on unworkable solutions.

The studies help decide whether to proceed to the conceptual design phase, assess potential alternatives and narrow the scope of your project.

These assessments will provide you with two crucial pieces of information:

- The feasibility of your project

- Whether the project can be delivered within budgetary constraints

We will develop a feasibility report and conduct a post-feasibility review to aid your decision-making process.

This service enables you to create schedules, resource plans and estimates for the subsequent stages of your project.

The key elements of our feasibility studies include:

- Exploration of all available options

- Outline engineering design in all disciplines

- Capital/operating cost estimates

- Risk analysis of environmental and safety factors

- Potential planning issues

All our feasibility studies are conducted by experienced engineers with advanced knowledge of the sector in which you operate.

Accurate, innovative design

We provide detailed, well-informed design services for all stages of the engineering process.

Optimise the design process by acquiring, collating and reviewing an extensive range of applicable literature and data.

Our research process involves a broad range of relevant, accurate information sources, including:

- Reverse engineering of existing designs

- Online/key text research (trade journals, vendor catalogues etc.)

- Legislative documentation, including governmental guidelines

Establish and evaluate cost-effective, low-risk ideas with our conceptual design process.

Conceptual design refines the recommendations of feasibility studies with the aim to identify the most cost-effective and efficient design which covers in more detail:

- Existing parameters and constraints

- Engineering Design Specification

- Identification of long materials and equipment

- Detailed cost and programme analysis

Establish and analyse the key requirements for your designs and identify potential problems in advance of the engineering stages.

To establish accurate design requirements, we consider:

- Functionality

- Attributes

- Specifications (determined by user needs assessment)

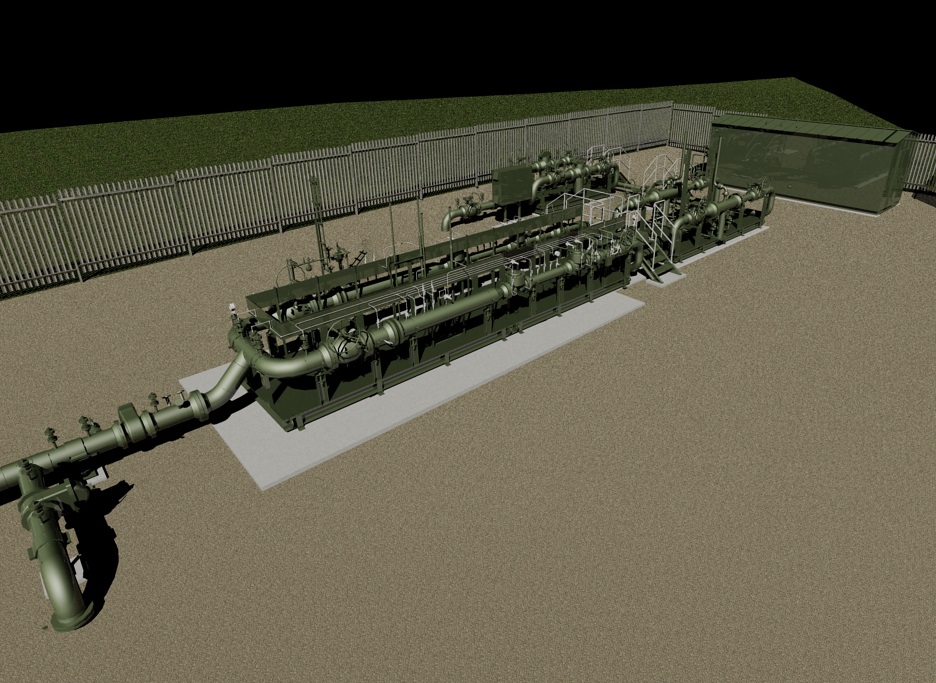

Define how you will turn your concept into a detailed design with our preliminary design/FEED process.

This process will outline your system configuration from a macro-perspective, providing you with:

- Schematics

- Diagrams

- Layouts

Establish a broad framework on which to develop your project that is flexible enough to accommodate amendments during the detailed design phase.

Develop your initial design into a deliverable asset by assessing all aspects of your project in detail.

This process adds to the preliminary design stage by incorporating:

- Materials procurement

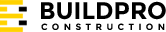

- 3D and linear modelling

- Technical drawings/specifications

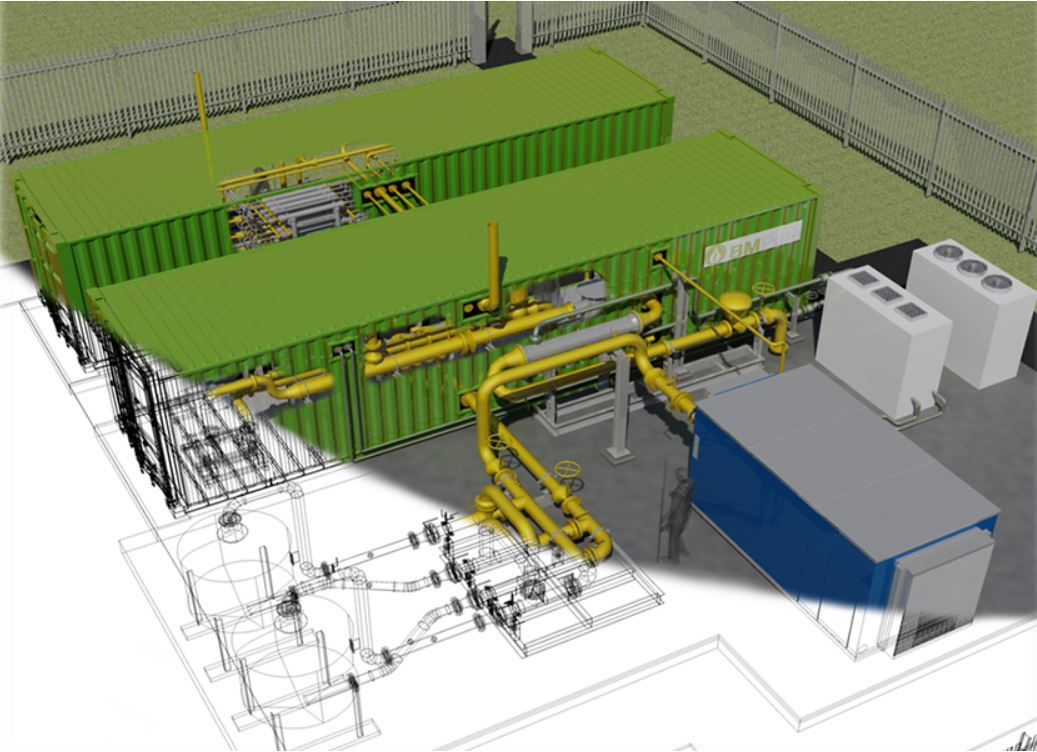

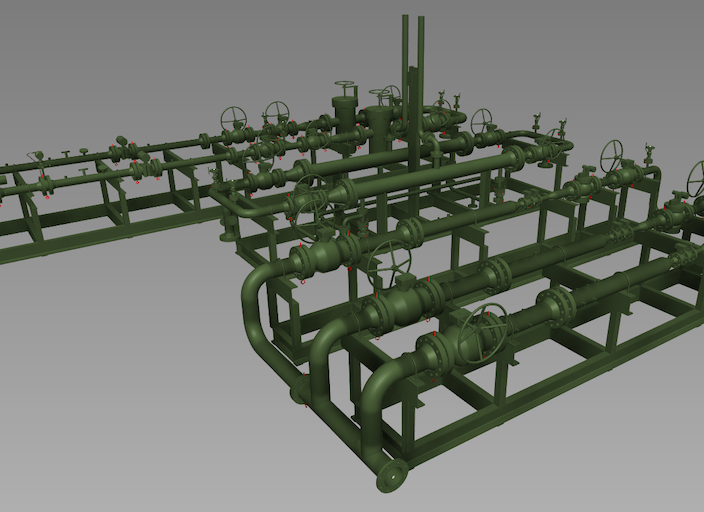

We design and supply skid units for the gas and process industries

This involves:

- Detailed design of the skid

- Procurement of specialist materials and equipment

- Fabrication and factory testing

- Delivery, site install and commissioning

EPC contracts that reduce risk

We provide engineering, procurement and construction (EPC) contractor (also known as ‘turnkey contractor’) services for all our specialist sectors.

Remove almost all risk and action your project with minimal resources by agreeing a lump sum turnkey (LSTK) contract that sets out a defined project timeline and budget. We can also work on a cost-reimbursable basis or use an alternative model.

You will be designated a single, experienced point of contact for the duration of your contract. You are welcome to send members of your team to inspect the project or embed themselves alongside our engineers.

The primary phases of our EPC contractor services include:

- Development of detailed engineering designs

- Procurement of required materials and equipment

- Construction of a fully operational facility

The EPC (or, ‘execution’) phase of a project typically follows the Front End Engineering Design (FEED) stage. This process enables the scope of works to be accurately specified, quantified and priced.

With this specification in place, you can be confident that the quality and performance of the finished development will not be compromised.